Cold forging press is our factory hot sale hydraulic press machine. Cold forging press is suitable for was mainly applied in to metal materials, cold forging, warm forging and extrusion molding, and punching mark, light stretching, cut edges and other materials. Such as cars, motorcycles, bicycles, cell phone case, LED radiator and heat sink, watchcase, hardware tools.

Cold forging can produce metal components to close tolerances and net shape, eliminating expensive secondary operations like machining.

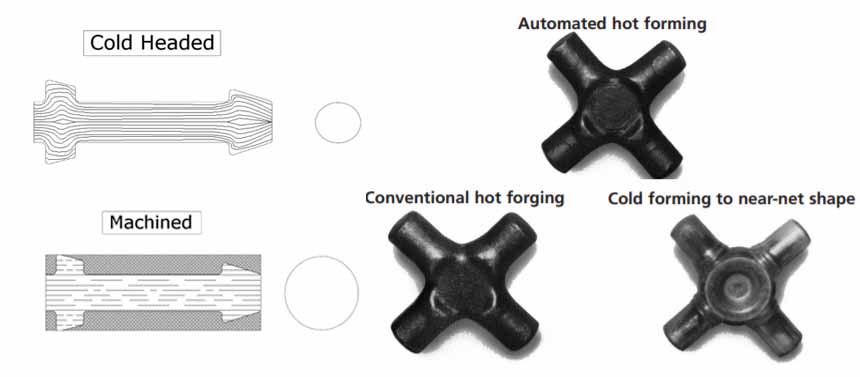

Material savings is evident in the image of the shaft (above). The shaft on the below is machined out of bar stock and results in approximately 64% loss of material. The shaft on the above is formed and extruded to form a head and nose. In addition to the saviungs because the material required to make the cold formed part is approximately 40 percent less. Cold forming the shaft produces a part with a far superior grain structure as shown by the lines above.

Additionally, parts produced by this precision forging process can routinely deliver higher properties than machined parts. In the case of extruded steel parts, mechanical properties can be as much as 40% greater. In fact, as compared to heat treated steels at the same hardness, cold-forged components produced from steel wire, rod, and bar permit use of up to 20% higher design yield strengths. Because cold forging is geared to high volume production and automation, it can be more cost-effective than alternative metal working processes.

Design flexibility, part consolidation, and elimination of labor-intensive secondary operations and heat treatment are among many reasons why cold forging is chosen. Although cold forging is commonly associated with high-volume components, it can be successfully utilized in any industry. As a rule of thumb, quantities approaching 10,000 pounds of parts per month are recommended to offset tooling costs.When materials more expensive than steel are employed, cold forging can be economical at lower quantities.

Process evolution sequence-from conventional hot forging to automated hot forming to cold forging-demonstrates how steel trunnions have edged closer to net shape. Significant cost reduction was achieved by elimination of an entire machining line, which was required to bring hot formed parts to final dimensions.

+86-13509801050

+86-13509801050

E-mail

E-mail