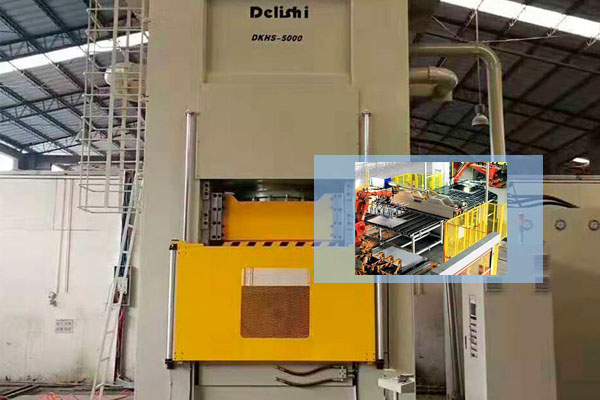

At Goodsjack/Delishi, we can design intelligent hydraulic presses to deliver reliable performance, precision and automation for the most demanding applications. Goodsjack/Delishi's 5000 ton intelligent hydraulic press customization solution, industrial solution with accuracy of ±0.02mm.

In industries requiring extreme force and precision—such as aerospace, automotive, and energy—a standard hydraulic press often falls short. A 5000 ton intelligent hydraulic press delivers unmatched power, enhanced by AI-driven control systems for optimal performance.

The first step in customization is a thorough understanding of the intended application. A 5000 ton intelligent hydraulic press can be used for a wide range of heavy-duty tasks.

● Forging: Hot or cold forging of large metal blanks (e.g., excavator bucket teeth, automotive components, aerospace parts, refractory materials).

● Deep Drawing: Forming large, complex shapes from sheet metal (e.g., auto side-members, stainless steel parts, aluminum pots).

● Stamping: High-tonnage stamping of various materials.

● Molding: Compression molding of large plastic or composite parts.

● Powder Compaction: Producing high-density components from powdered materials.

● Specialty Applications: Forming bipolar plates for fuel cells, fireproofing bricks, etc.

Hydraulic presses have powered industry for decades—but intelligent 5000 ton systems redefine what's possible. By merging brute force with machine learning, these presses deliver unprecedented accuracy and efficiency. If you need custom hydraulic machine solution, please contac us for your own project.

+86-13509801050

+86-13509801050

E-mail

E-mail